Analyze Hydrocarbons on OPN/Res-Sil C Bonded GC Packing

Superior Replacement for Porasil Packings

- Unique separations of saturated and unsaturated hydrocarbons.

- Innovative bonding chemistry for batch-to-batch reproducibility, excellent thermal stability, and long life.

- Other bonded phases available.

For years, Porasil C and Porasil B, modified with covalently attached liquid phases such as OPN (cyanopropyl) or n-octane functional groups, offered important advantages, relative to conventional GC packings, in analyses of C1-C4 hydrocarbons: faster separations, higher thermal stability, shorter conditioning times, and longer lifetimes. Porasil C / Porasil B products were discontinued in the 1980s, however, and inventories have been depleted, forcing those that used these packings to search for comparable materials.

Restek chemists solved the problem by developing Res-Sil C and Res-Sil B bonded packings. These packings afford all of the advantages of the Porasil C and Porasil B materials, with the added advantage of consistent batch-to-batch performance - and they are readily available for immediate delivery. Compared to diatomaceous earth media, Res-Sil C has a small surface area, good inertness, low friability, and less reactivity.

Unique Selectivity for Process GC and High-Speed Analysis

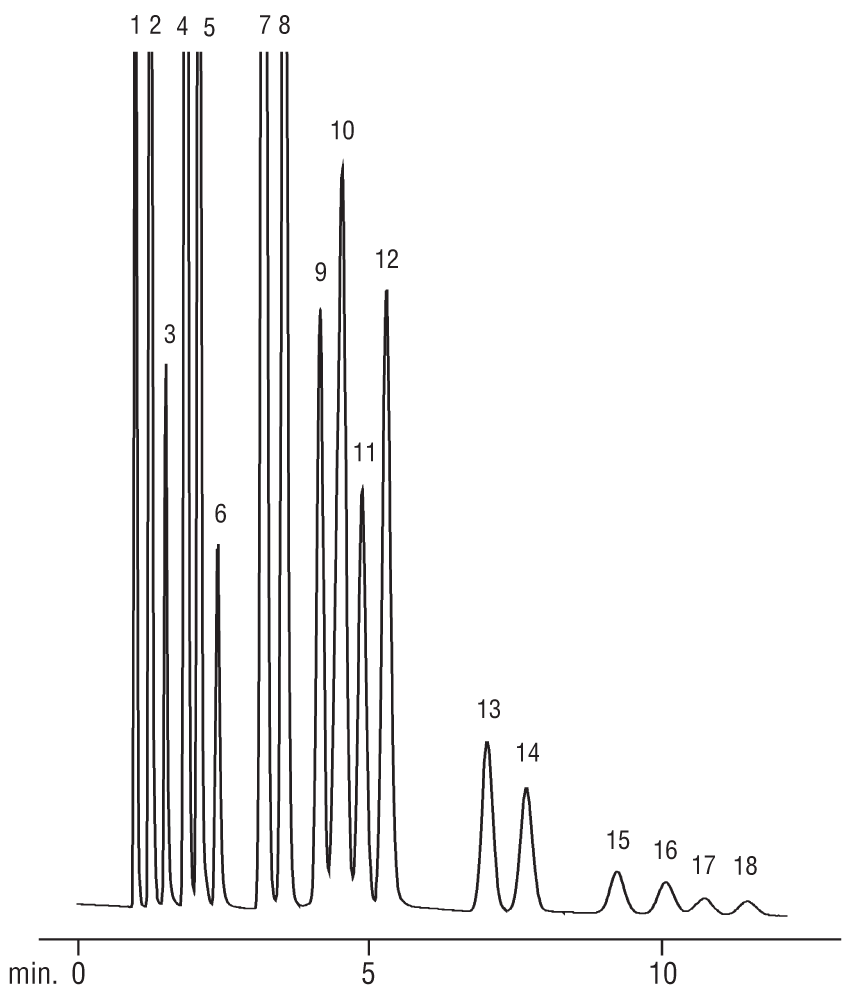

Speed of analysis is crucial in process GC, and in laboratory gas analyzers in which multiple columns and valve switching are used to separate complex gas mixtures. Res-Sil C bonded packings are ideal for resolving the difficult-to-separate saturated and unsaturated C4 hydrocarbons under these demanding conditions. Figure 1 illustrates the unique selectivity of OPN on Res-Sil C packing for eluting cis-2-butene before 1,3-butadiene. When used in series with other columns, this unique material provides petroleum and petrochemical method developers with a powerful tool for fast determination of C1-C4 hydrocarbons [1].

Stringent QA Assures Batch-to-Batch Consistency

Historically, one of the problems with bonded phases on Porasil media was batch-to-batch variations in the amount of liquid stationary phase incorporated on the silica support. Through our new synthesis pathways, we precisely control the amount of bonded liquid phase on Res-Sil C in every batch of packing, assuring reproducible retention times and separations. Each batch of packing is tested with a complex mixture of hydrocarbons, to confirm it meets demanding retention time and retention index specifications. We evaluate column bleed at the recommended maximum temperature, 150 °C, to ensure that there are no retention shifts or elevated baselines.

In addition to OPN on Res-Sil C packing, we bond n-octane and Carbowax 1540 phases to Res-Sil C. Each of these packings offers a conditioning time of less than 30 minutes, low bleed, long lifetime, and consistent batch-to-batch reproducibility. We test every batch of every Restek bonded phase packing for bleed, efficiency, retention index, and retention time reproducibility. In addition, we make a broad range of packed and micropacked columns in specially-deactivated Silcosteel tubing, for superior inertness and efficiency.

If you have been looking for a replacement for a Porasil C or Porasil B packing, we invite you to contact us. Your search should end here.

Figure 1: OPN on Res-Sil C packing has unique selectivity for cis-2-butene and 1,3-butadiene.

| Peaks | Retention Indices | |

|---|---|---|

| 1. | Methane | 100 |

| 2. | Ethane/ethylene | 200 |

| 3. | Acetylene | 260 |

| 4. | Propane | 300 |

| 5. | Propylene | 321 |

| 6. | Propadiene | 345 |

| 7. | Isobutane | 386 |

| 8. | Butane | 400 |

| 9. | 1-Butene | 422 |

| Peaks | Retention Indices | |

|---|---|---|

| 10. | Isobutylene/trans-2-butene | 434 |

| 11. | cis-2-Butene | 443 |

| 12. | 1,3-Butadiene | 454 |

| 13. | Isopentane | 488 |

| 14. | Pentane/3-methyl-1-butene | 503 |

| 15. | 1-Pentene | 522 |

| 16. | trans-2-Pentene | 533 |

| 17. | cis-2-Pentene | 540 |

| 18. | 2-Methyl-2-butene | 549 |

| Column | OPN, 80/100 mesh on Res-Sil C packing, SilcoSmooth tubing, 12 ft., 1/8 in. OD, 2 mm ID (cat.# 80437-800) |

|---|---|

| Standard/Sample | Refinery gas |

| Conc.: | 0.1-6 absolute mole % |

| Injection | |

| Inj. Vol.: | 20 µL packed on-column |

| Inj. Temp.: | 200 °C |

| Oven | |

| Oven Temp.: | 50 °C |

| Carrier Gas | He, constant flow |

| Flow Rate: | 30 mL/min |

| Detector | FID @ 200 °C |

|---|---|

| Acknowledgement | Standard courtesy of AC Analytical Controls |

References

- Saha, N.C., S.K. Jain, and R.K. Dua. J. Chromatogr. Sci. 16: 323-328 (1978). Reference not available from Restek.