GC Column Installation Made Easier with Extended Reducing Nuts for the Agilent Split/Splitless Inlet

Every new Agilent GC comes with an insulating cup (also known as a nut warmer cup with insulation) that is installed over the bottom of the split/splitless inlet. The purpose of this insulating cup is to protect the bottom of the inlet from the temperature fluctuations of the GC oven during a temperature ramp. Unfortunately, this insulating cup makes it difficult to install a GC column. The column installation is typically done “blind” as the user cannot see the reducing nut at the bottom of the inlet. Removal of the insulating cup makes it easier to install the GC column and as such, once the insulating cup is removed, it is rarely reinstalled.

While some analysts run their GCs without the insulating cup and get satisfactory results, unless you compare analyses with and without the insulating cup, you don’t know how good “good” can be. In Figure 1 we show low volatility pesticides, with one analysis using the insulating cup and with the other analysis not using the insulating cup. You can see from the difference in peak heights that you get better analyte responses with the insulating cup installed.

Figure 1: Higher analyte responses result from analysis with the insulating cup (nut warmer cup) installed, especially for lower volatility pesticides.

Not only do you get better analyte response by using the insulating cup, you also see improved repeatability with it installed. Table I shows the analysis of several pesticides using a 4 mm single taper liner with wool at the bottom. The initial oven temperature was set at 90 °C and seven injections were made. As you can see, when the insulating cup is used, the percent relative standard deviation (RSD) for the peak areas of all compounds is under 6%; whereas, for the analyses when the insulating cup is not used, percent RSD ranged from the mid-twenties up to 45% RSD. For more on the benefits of using the insulating cup, visit our nut warmer cup technical blogs.

Table I: More consistent results were achieved when analyzing pesticides with the insulating cup installed compared to analysis without it in place. (n = 7)

| Percent RSD | ||

|

Pesticide |

Without Insulating Cup |

With Insulating Cup |

|

4,4’-DDT |

24 |

4.0 |

|

Bifenthrin |

24 |

3.9 |

|

Fenpropathrin |

26 |

4.2 |

|

cis-Permethrin |

31 |

4.3 |

|

trans-Permethrin |

34 |

4.3 |

|

Deltamethrin |

45 |

5.6 |

As previously stated, the main reason that a user would remove the insulating cup would be to facilitate the installation of the GC column since, with the insulating cup installed, the user would have trouble seeing the bottom of the inlet. Using a Restek extended reducing nut instead of a standard reducing nut makes column installation easier, as the threaded opening of the inlet where you install the GC column is more visible beneath the bottom of the insulating cup. Note that while the extended reducing nut simplifies column installation by improving visibility, it does not change the column installation distance (i.e., the length from the top of the ferrule to the end of the column).

Figure 2: An extended reducing nut is visible below the insulating cup, making column installation much simpler.

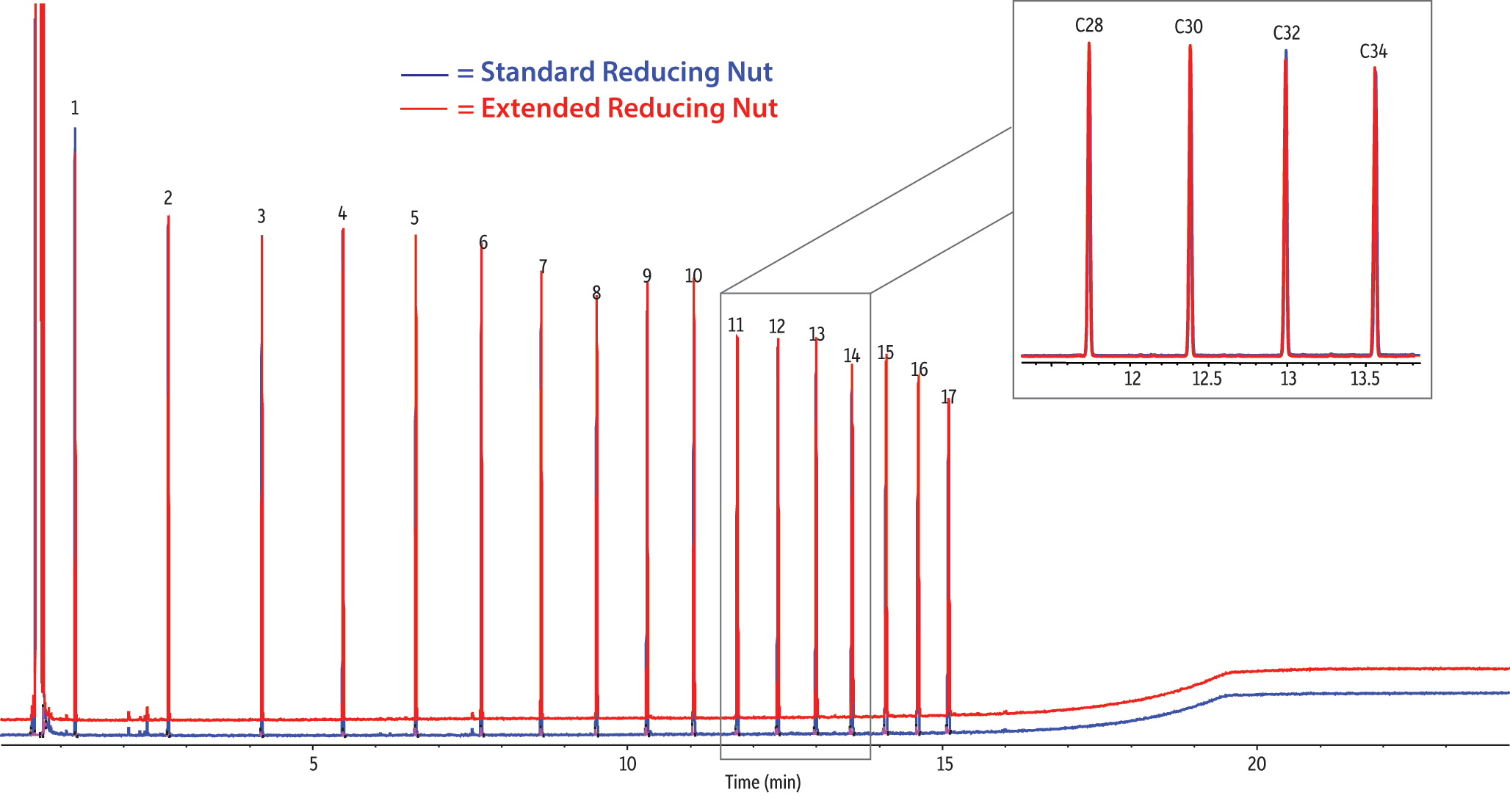

Restek's extended reducing nuts, which are used with extended capillary column nuts, perform similarly to the original standard capillary nut. To demonstrate this, a hydrocarbon test mix containing n-alkanes covering a wide range of volatilities was analyzed. Multiple analyses on the extended reducing nut were compared to multiple analyses on the standard reducing nut. The ratio of peak area for C40 versus C8 was used to determine if any discrimination was seen between these two styles of reducing nuts. The average ratio of the C40 to C8 areas for the standard capillary nut was 1.01. The average ratio of the C40 to C8 areas for the extended capillary nut was 1.04. There was no difference between the performances of these two capillary nuts. Figure 3 shows an overlay of two chromatograms, one showing this analysis on a standard reducing nut and one showing this analysis on the extended reducing nut.

Figure 3: Overlay of a Standard Reducing Nut vs. Restek Extended Reducing Inlet Nut while running FL TRPH Standard.

| Peaks | tR (min) | |

|---|---|---|

| 1. | Octane | 1.23 |

| 2. | Decane | 2.70 |

| 3. | Dodecane | 4.18 |

| 4. | Tetradecane | 5.48 |

| 5. | Hexadecane | 6.64 |

| 6. | Octadecane | 7.68 |

| 7. | Eicosane | 8.63 |

| 8. | Docosane | 9.50 |

| Peaks | tR (min) | |

|---|---|---|

| 9. | n-Tetracosane | 10.30 |

| 10. | n-Hexacosane | 11.04 |

| 11. | n-Octacosane | 11.73 |

| 12. | n-Triacontane | 12.38 |

| 13. | n-Dotriacontane | 12.98 |

| 14. | n-Tetratriacontane | 13.55 |

| 15. | n-Hexatriacontane | 14.09 |

| 16. | n-Octatriacontane | 14.60 |

| 17. | n-Tetracontane | 15.08 |

| Column | Rxi-1HT, 15 m, 0.32 mm ID, 0.10 µm (cat.# 13953) |

|---|---|

| Standard/Sample | Florida TRPH standard (cat.# 31266) |

| Diluent: | Hexane |

| Conc.: | 50 ppm 1 ng on column |

| Injection | |

| Inj. Vol.: | 1 µL split (split ratio 50:1) |

| Liner: | Premium 4.0 mm ID Precision inlet liner w/wool (cat.# 23305) |

| Inj. Temp.: | 300 °C |

| Split Vent Flow Rate: | 114 mL/min |

| Oven | |

| Oven Temp.: | 40 °C (hold 1.0 min) to 400 °C at 20 °C/min |

| Carrier Gas | He, constant flow |

| Flow Rate: | 2.3 mL/min |

| Linear Velocity: | 55 cm/sec @ 40 °C |

| Detector | FID @ 400 °C |

|---|---|

| Make-up Gas Flow Rate: | 45 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 40 mL/min |

| Air flow: | 450 mL/min |

| Data Rate: | 50 Hz |

| Instrument | Agilent/HP6890 GC |

Based on the data shown here, keeping the insulating cup installed on your GC can improve both peak response and analytical reproducibility. In order to reap the benefits of using the insulating cup while keeping column installation easy, we recommend replacing standard reducing nuts with extended reducing nuts for the Agilent split/splitless GC inlet. This simple change improves visibility of the nut during column installation and does not affect chromatographic performance.