PAL Smart SPME Arrow

Set Your Sights on Superior Performance

- Rugged, stainless-steel construction ensures longer lifetimes.

- Faster extraction means higher sample throughput.

- Better sensitivity allows lower LODs.

- Choose format based on sampling technique:

- 1.1 mm sleeve, if only using headspace sampling.

- 1.5 mm wide sleeve, if using direct immersion sampling (works for headspace, too).

- Now with Smart technology—each SPME Arrow is equipped with a unique Smart chip containing parameters, ranges, and usage history.

Solid phase microextraction (SPME) is a fast, automated sample preparation technology that reduces sample handling, extraction time, and solvent consumption, making it a popular choice in environmental, food, and clinical laboratories. However, traditional SPME fiber technology has some significant drawbacks, including poor mechanical stability and a small phase volume.

The PAL Smart SPME Arrow system is a revolutionary change in microextraction that combines exceptional robustness with faster extraction times and trace-level sensitivity (Table I). In contrast to traditional SPME fibers, SPME Arrows contain significantly more phase volume, which allows more target analyte to be extracted in less time. In addition, the stainless-steel construction, unique Arrow tip, inner stabilizing rod, and outer sheath design fully protect the phase, minimizing both mechanical damage and analyte loss during sample transfer.

Table I: Comparing Restek PAL SPME Arrow to Traditional SPME Fiber (Headspace Technique)

|

Traditional Fibers |

1.1 mm Arrow |

1.5 mm Arrow |

The Arrow Advantage |

|

|

Rugged, stainless-steel construction

|

No |

Yes |

Yes |

|

|

Surface area |

9.4 mm2 |

44 mm2 |

63 mm2 |

Increase sample throughput—higher surface area lets you reduce extraction time and analyze more samples per shift. |

|

Phase (PDMS) volume |

0.6 μL |

3.8 μL |

12 μL |

With significantly more phase, SPME Arrow provides better sensitivity so you can lower detection limits with confidence. |

On Target: Longer Lifetime

One of the main drawbacks to SPME fibers is their fragility. Even during routine use, they are easily damaged and can be irreparably broken (Figure 1). Busy labs will benefit greatly from the reliability of the rugged Restek PAL Smart SPME Arrow. The unique, stainless-steel Arrow design includes a robust inner stabilizing rod that resists bending and breakage as well as an outer sheath that protects the phase coating and prevents both physical damage and analyte loss. Typically, SPME Arrows perform well for hundreds of extractions, lasting two to three times longer than traditional SPME fibers. In addition, the unique arrow-shaped tip pierces the septum cleanly and with little resistance, extending septum lifetime (Figure 2).

Figure 1: SPME fibers break easily during routine operation.

Figure 2: The rugged construction of the Restek PAL SPME Arrow prevents breakage under normal use.

Which Restek PAL SPME Arrow is best for my application?

Restek PAL Smart SPME Arrows are suitable for a wide range of analyte chemistries and sample matrices. They are suitable for manual injection and are fully backwards compatible with any generation of PAL3 Systems. Choose the best SPME Arrow for your application based on the properties of your target compounds. Note that a GC inlet conversion kit is required in order to use a Restek PAL SPME Arrow.

- Trace analysis in foodstuffs

- Drugs and pharmaceuticals

- Herbicides/pesticides

- Medical diagnostics

- Trace impurities in polymers and solid samples

- Solvent residues in raw materials

- Water analysis (organics in water)

| Analytes* | Molecular Weight† | Material | Thickness (µm) | Needle Diameter (mm) | Hub Color | Smart SPME Arrow Each (cat.#) |

Smart SPME Arrow 3-pk (cat.#) |

| Volatile | 60–275 | Polydimethylsiloxane (PDMS) | 100 | 1.1 | Red | 28906-1 | 28906-3 |

| Volatile | 60–275 | Polydimethylsiloxane (PDMS) | 100 | 1.5 | Red | 28910-1 | 28910-3 |

| Volatile (high capacity) | 60–275 | Polydimethylsiloxane (PDMS) | 250 | 1.5 | Black | 28911-1 | 28911-3 |

| Polar, semivolatile | 80–300 | Polyacrylate (PA) | 100 | 1.1 | Gray | 28902-1 | 28902-3 |

| Highly volatile | 30–225 | Carbon Wide Range/ Polydimethylsiloxane (Carbon-WR/PDMS) |

120 | 1.1 | Light Blue | 28903-1 | 28903-3 |

| Highly volatile | 30–225 | Carbon Wide Range/ Polydimethylsiloxane (Carbon-WR/PDMS) |

120 | 1.5 | Light Blue | 28907-1 | 28907-3 |

| Aromatic, semivolatile | 60–300 | Divinylbenzene/ Polydimethylsiloxane (DVB/PDMS) |

120 | 1.1 | Violet | 28905-1 | 28905-3 |

| Aromatic, semivolatile | 60–300 | Divinylbenzene/ Polydimethylsiloxane (DVB/PDMS) |

120 | 1.5 | Violet | 28909-1 | 28909-3 |

| Volatile and semivolatile | 40–275 | Divinylbenzene/ Carbon Wide Range/ Polydimethylsiloxane (DVB/Carbon-WR/PDMS) |

120 | 1.1 | Dark Gray | 28904-1 | 28904-3 |

| Volatile and semivolatile | 40–275 | Divinylbenzene/ Carbon Wide Range/ Polydimethylsiloxane (DVB/Carbon-WR/PDMS) |

120 | 1.5 | Dark Gray | 28908-1 | 28908-3 |

| PAL Smart SPME Arrow Method Development Kit (one Smart SPME arrow each: 1.1 mm PA 100 μm, 1.1 mm Carbon-WR/PDMS 120 μm; 1.1 mm DVB/PDMS 120 μm; 1.1 mm PDMS 100 μm; 1.1 mm DVB/Carbon-WR/PDMS 120 μm). | 28901 (kit) | ____ | |||||

*Recommended maximum GC inlet pressure is 50 psi or less.

All Restek PAL SPME Arrows have 20 mm of stationary phase bonded onto stainless steel.

†These molecular weight ranges are a reasonable approximation; however, end users should verify suitability for their specific application.

On Target: Higher Sample Throughput

Restek PAL Smart SPME Arrows provide much faster extraction times than traditional SPME fibers because Arrows have much more phase volume. As shown in Figure 3, the increased phase volume allows more target analyte to be extracted in just seconds using an Arrow than can be extracted from a traditional fiber. Being able to extract what you need in a fraction of the time means more samples can be analyzed per day, which improves lab efficiency and profitability. The example in Table II demonstrates a nearly 50% increase in productivity!

Figure 3: Benchmark Comparison of 1.1 mm SPME Arrow vs. Standard SPME Fiber for 2.5 ppb Volatiles in Headspace

Table II: Analyze more samples per day with Restek PAL SPME Arrow.

| Sample Collection and Desorption Steps with Associated Times (sec) | ||||||||

|

Select Sample Vial |

Vial Incubation / Fiber Conditioning |

Vial Transfer |

Sample Extraction (Headspace) |

GC Equilibration |

Desorb Fiber |

Return Sample Vial |

Total Time |

Samples per Day |

| Target Analytes: Traditional SPME Fiber | ||||||||

|

22 |

120 |

20 |

120 |

15 |

10 |

15 |

322 |

268 |

| Target Analytes: SPME Arrow | ||||||||

|

22 |

120 |

20 |

15 |

15 |

10 |

15 |

217 |

398 (~50% increase) |

Note: Processes that take <10 sec to perform were omitted from the table. Actual samples per day is dependent on GC cycle time.

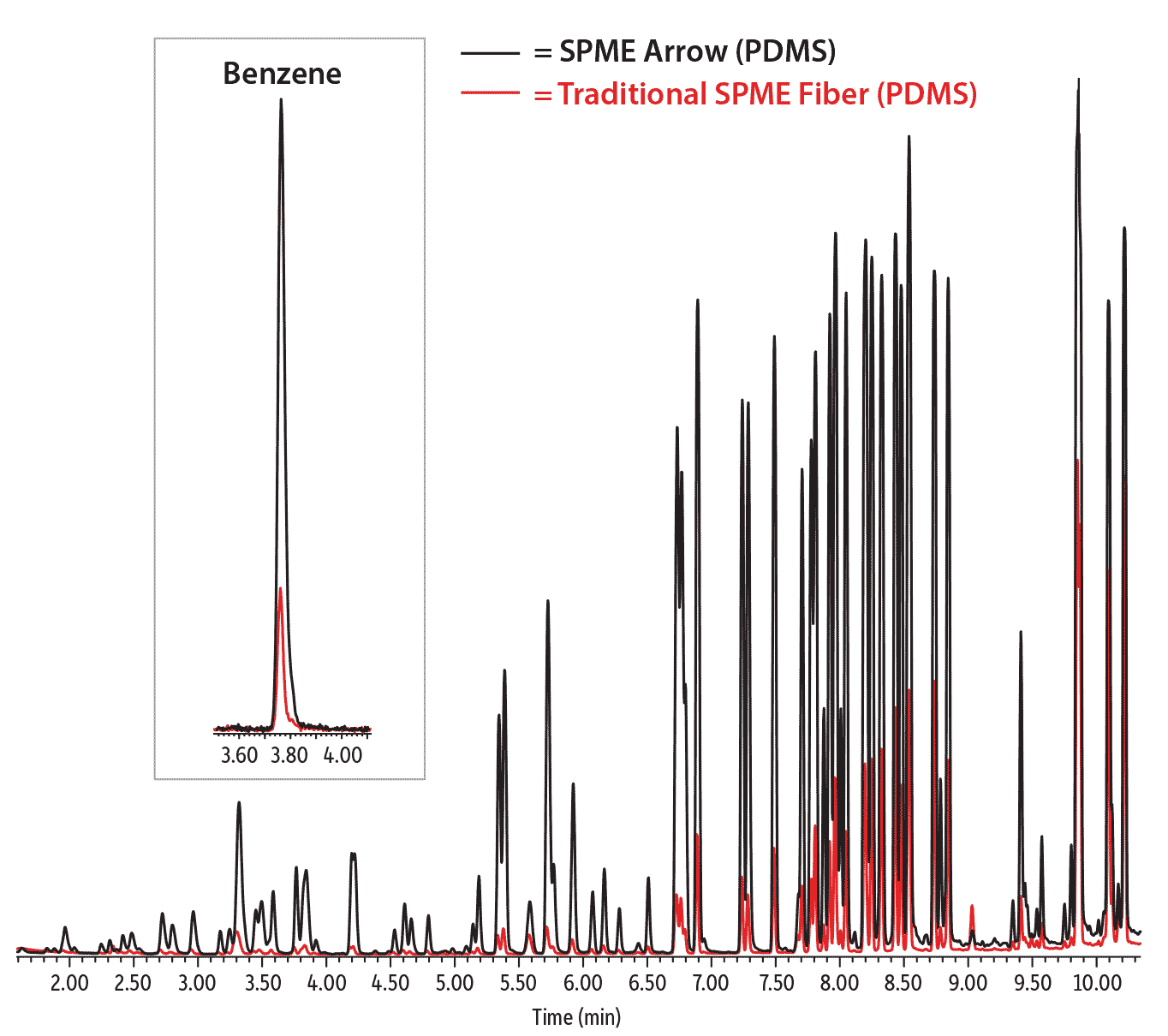

On Target: Lower Detection Limits

Developing a new method or trying to improve the performance of an existing one? Restek PAL Smart SPME Arrows have more phase volume, so they provide much greater sensitivity than traditional fibers. To demonstrate this, 82 volatile compounds were analyzed under three different headspace extraction time and extraction volume combinations. Results under all experimental conditions definitively show that Arrow outperforms traditional SPME fiber and provides much higher analyte responses (Table III and Figure 4).

Table III: Analyte response is much higher with SPME Arrow than with a traditional SPME fiber.

| Average % Increase in Response of Arrow vs. Traditional Fiber |

|||

|

Extraction Time (min) |

Extraction Volume (mL Water) |

1.1 mm Arrow |

1.5 mm Arrow |

|

10 |

10 |

297% |

527% |

|

5 |

10 |

618% |

896% |

|

10 |

5 |

446% |

634% |

Figure 4: Restek PAL SPME Arrow extracts more target analyte from samples, allowing lower detection limits.

| Column | Rtx-VMS, 30 m, 0.25 mm ID, 1.40 µm (cat.# 19915) |

|---|---|

| Standard/Sample | 2-Chloroethyl vinyl ether (cat.# 30265) |

| 8260 MegaMix calibration mix (cat.# 30633) | |

| 8260 Surrogate mix (cat.# 30073) | |

| VOA calibration mix #1 (ketones) (cat.# 30006) | |

| California oxygenates mix (cat.# 30465) | |

| 502.2 Calibration mix #1 (gases) (cat.# 30042) | |

| 8260 Internal standard mix (cat.# 30074) | |

| Diluent: | Water |

| Conc.: | 50 ng/mL |

| Injection | split (split ratio 10:1) |

| Liner: | Topaz 1.8 mm ID straight/SPME inlet liner (cat.# 23280) |

| Inj. Temp.: | 250 °C |

| Oven | |

| Oven Temp.: | 40 °C (hold 1 min) to 100 °C at 12 °C/min (hold 0 min) to 240 °C at 25 °C/min (hold 1.6 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.0 mL/min |

| Linear Velocity: | 44.411 cm/sec @ 40 °C |

| Detector | MS | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mode: | Scan | ||||||||

| Scan Program: | |||||||||

| |||||||||

| Transfer Line Temp.: | 250 °C | ||||||||

| Analyzer Type: | Quadrupole | ||||||||

| Source Type: | Extractor | ||||||||

| Extractor Lens: | 3 mm ID | ||||||||

| Source Temp.: | 300 °C | ||||||||

| Quad Temp.: | 150 °C | ||||||||

| Electron Energy: | 70.0 eV | ||||||||

| Tune Type: | manual | ||||||||

| Ionization Mode: | EI | ||||||||

| Instrument | Agilent 7890B GC & 5977A MSD | ||||||||

| Acknowledgement | CTC Analytics AG | ||||||||

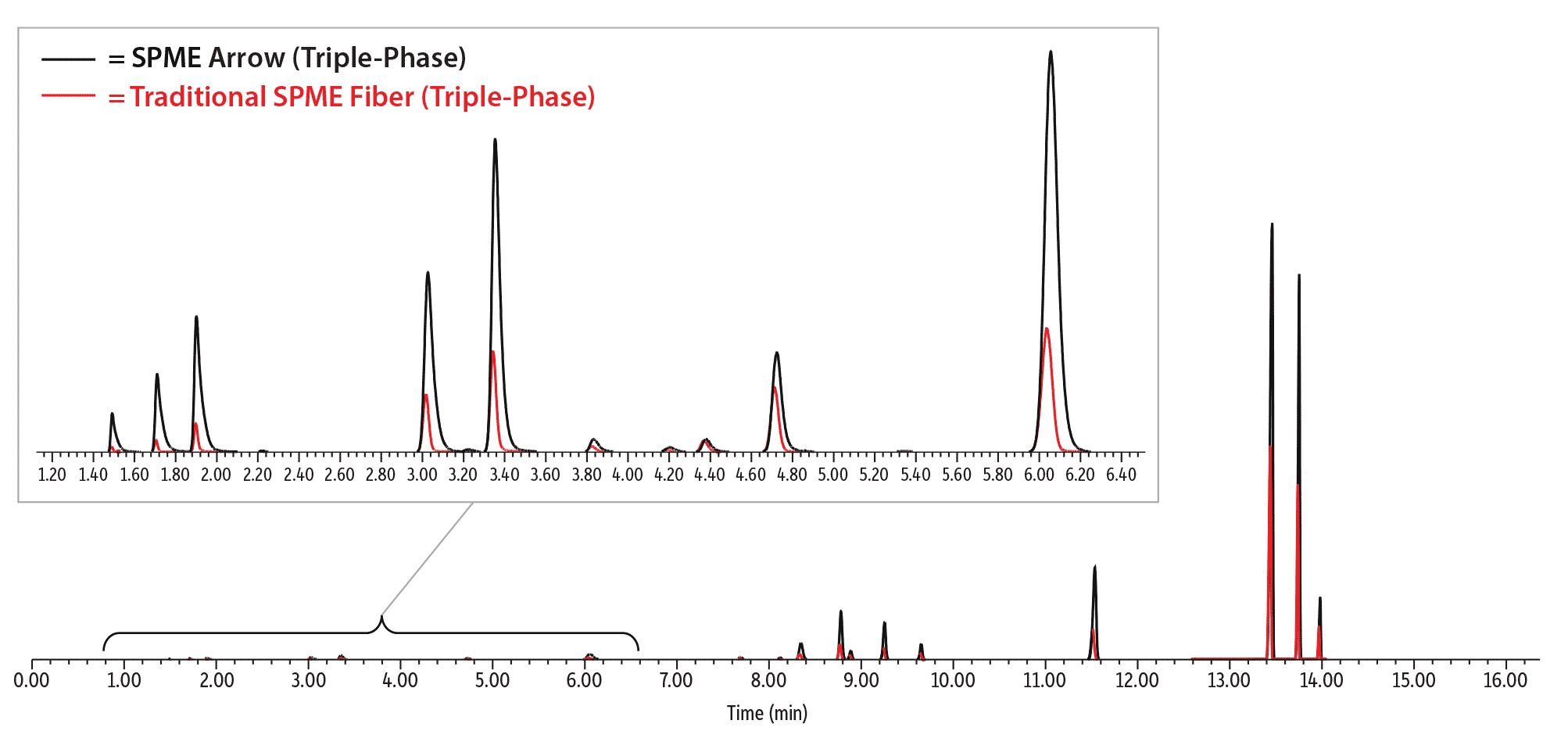

Turning to the emerging cannabis market and the triple-phase (DVB/Carbon WR/PDMS) Arrow, you can also expect significantly higher analyte responses with residual solvents and other classes of compounds (Figure 5).

Figure 5: Restek PAL SPME Arrow provides similarly superior results for residual solvents and other compounds.

| Peaks | |

|---|---|

| 1. | n-Propane |

| 2. | Isobutane |

| 3. | n-Butane |

| 4. | Methanol |

| 5. | n-Pentane |

| 6. | Ethanol |

| 7. | Diethyl ether |

| 8. | Acetone |

| 9. | 2-Propanol |

| 10. | Acetonitrile |

| 11. | Methylene chloride |

| 12. | n-Hexane |

| Peaks | |

|---|---|

| 13. | Ethyl acetate |

| 14. | Chloroform |

| 15. | Cyclohexane |

| 16. | Benzene |

| 17. | 1,2-Dichlorethane |

| 18. | n-Heptane |

| 19. | Trichloroethene |

| 20. | Toluene |

| 21. | m-Xylene |

| 22. | p-Xylene |

| 23. | o-Xylene |

| 24. | N,N-Dimethylacetamide (solvent) |

Figure 6: Traditional SPME fibers cannot match the extraction yield of SPME Arrows (immersion extraction technique).