Topaz GC Inlet Liners

Patented Topaz GC inlet liners feature revolutionary technology and inertness to deliver the next level of True Blue Performance:

- Deactivation—unbelievably low breakdown for accurate and precise low-level GC analyses.

- Reproducibility—unbeatable manufacturing controls and QC testing for superior reliability across compound classes.

- Productivity—unparalleled cleanliness for maximized GC uptime and lab throughput.

The Next Level of True Blue Deactivation

As the demand for lower detection limits continues to grow, even the smallest amount of activity in your liner can cause analyte breakdown and impact your results—tailing peaks, loss of response, and other issues we’ve all experienced. In developing Topaz GC inlet liners, our chemists created a new deactivation that yields unbelievably low breakdown.

Liner inertness can be described as the reduction in unwanted reactions between a liner and active compounds (and, therefore, a reduction in analyte breakdown and adsorption). Topaz deactivation technology thoroughly passivates the liner—and the wool inside—so that your liner is highly inert to a wide array of reactive analytes. This inertness increases peak symmetry and response, leading to better quantitation, accuracy, and precision.

With deactivated Topaz liners, you prevent unwanted chemical interactions and minimize breakdown, which improves your data quality and dependability and reduces instrument downtime. Even for low-level GC analysis of highly sensitive compounds—like 2,4-DNP, carbaryl, endrin, and DDT—these highly inert liners provide high-quality results that you’ll have to see for yourself to believe.

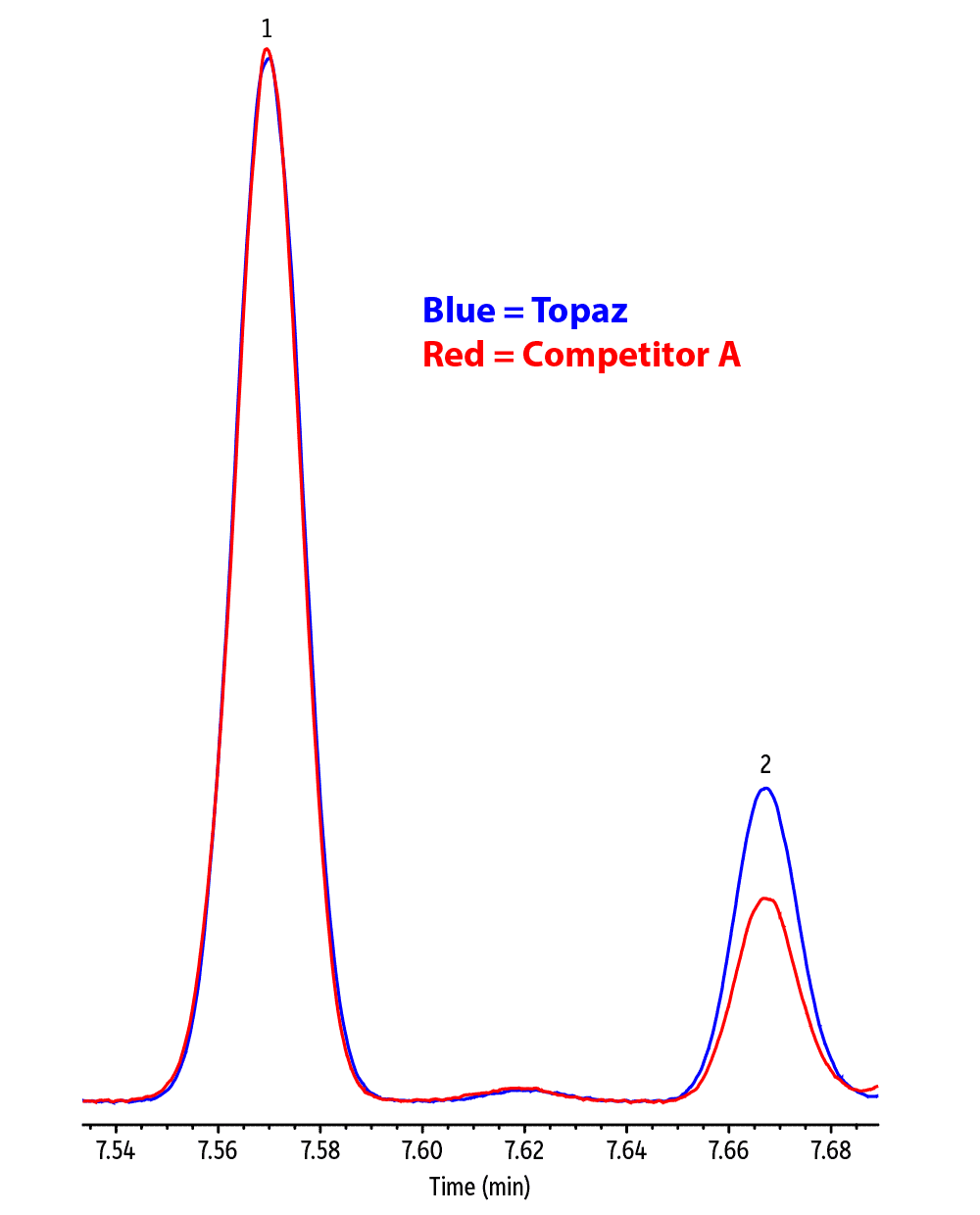

Figure 1: High inertness is important, especially when using wool. Comparatively testing liners using highly reactive 2,4-DNP shows the competition simply can’t compete.

| Peaks | Conc. (µg/mL) | |

|---|---|---|

| 1. | Acenaphthene (IS) | 1 |

| 2. | 2,4-Dinitrophenol (DNP) | 1 |

| Column | Rxi-5ms, 15 m, 0.25 mm ID, 0.25 µm (cat.# 13420) |

|---|---|

| Standard/Sample | Topaz FID liner test mix |

| Diluent: | Methylene chloride |

| Injection | |

| Inj. Vol.: | 1 µL splitless (hold 1 min) |

| Liner: | Topaz 4.0 mm ID single taper with wool (cat.# 23303) |

| Inj. Temp.: | 250 °C |

| Purge Flow: | 40 mL/min |

| Oven | |

| Oven Temp.: | 40 °C (hold 1 min) to 300 °C at 18.5 °C/min (hold 1 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 2 mL/min |

| Detector | FID @ 340 °C |

|---|---|

| Make-up Gas Flow Rate: | 45 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 40 mL/min |

| Air flow: | 400 mL/min |

| Data Rate: | 50 Hz |

| Instrument | Agilent 7890A GC |

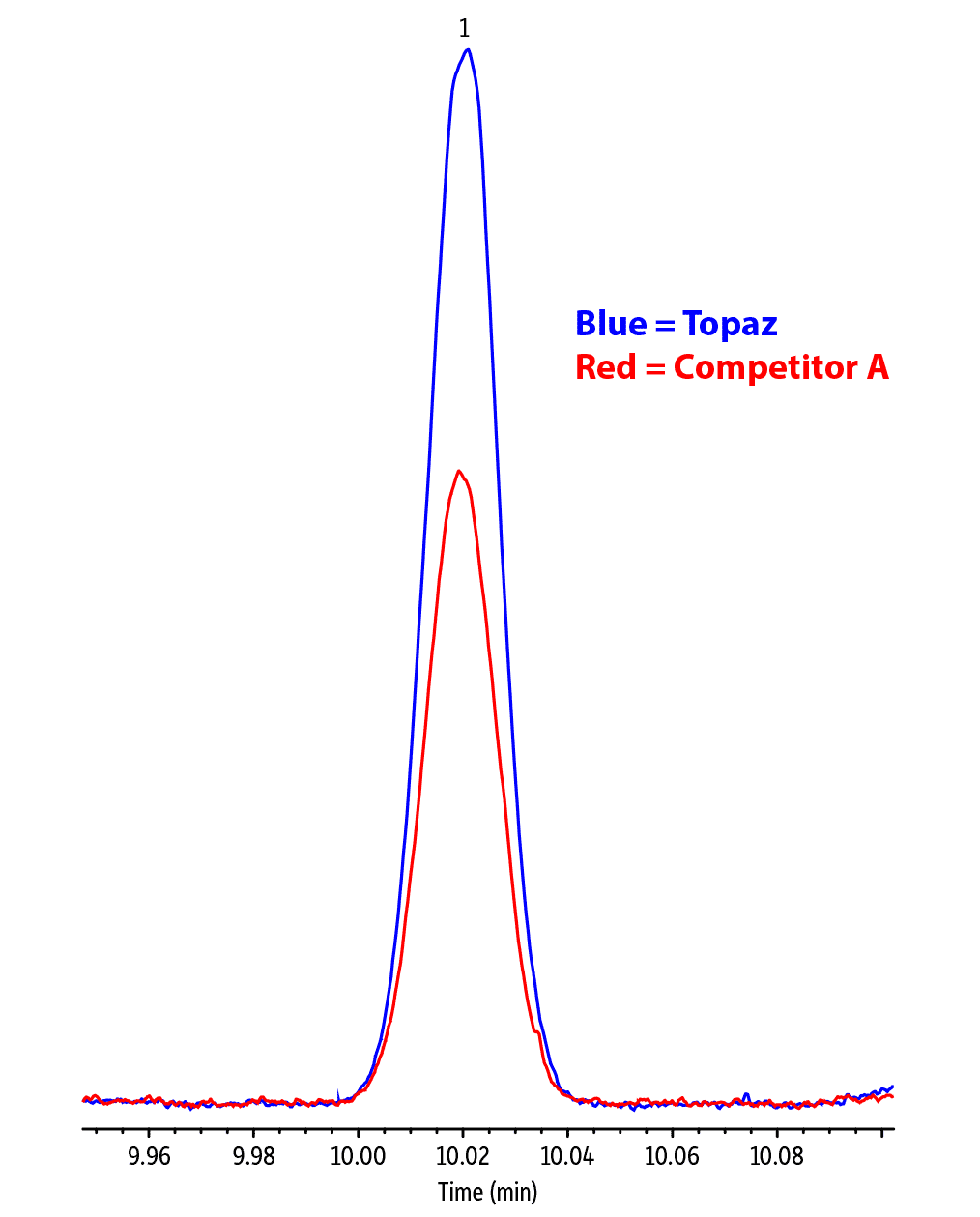

Figure 2: Regardless of your industry, carbaryl is an indicator of whether a liner has the inertness needed for trace-level work. Once again, Topaz outperforms the competition.

| Peaks | tR (min) | Conc. (µg/mL) | |

|---|---|---|---|

| 1. | Carbaryl | 10.019 | 0.5 |

| Column | Rxi-5ms, 15 m, 0.25 mm ID, 0.25 µm (cat.# 13420) |

|---|---|

| Standard/Sample | Topaz FID liner test mix |

| Diluent: | Methylene chloride |

| Conc.: | 0.5 µg/mL |

| Injection | |

| Inj. Vol.: | 1 µL splitless (hold 1 min) |

| Liner: | Topaz 4.0 mm ID single taper liner with wool (cat.# 23303) |

| Inj. Temp.: | 250 °C |

| Purge Flow: | 40 mL/min |

| Oven | |

| Oven Temp.: | 40 °C (hold 1 min) to 300 °C at 18.5 °C/min (hold 1 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 2 mL/min |

| Detector | FID @ 340 °C |

|---|---|

| Make-up Gas Flow Rate: | 45 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 40 mL/min |

| Air flow: | 400 mL/min |

| Data Rate: | 50 Hz |

| Instrument | Agilent 7890A GC |

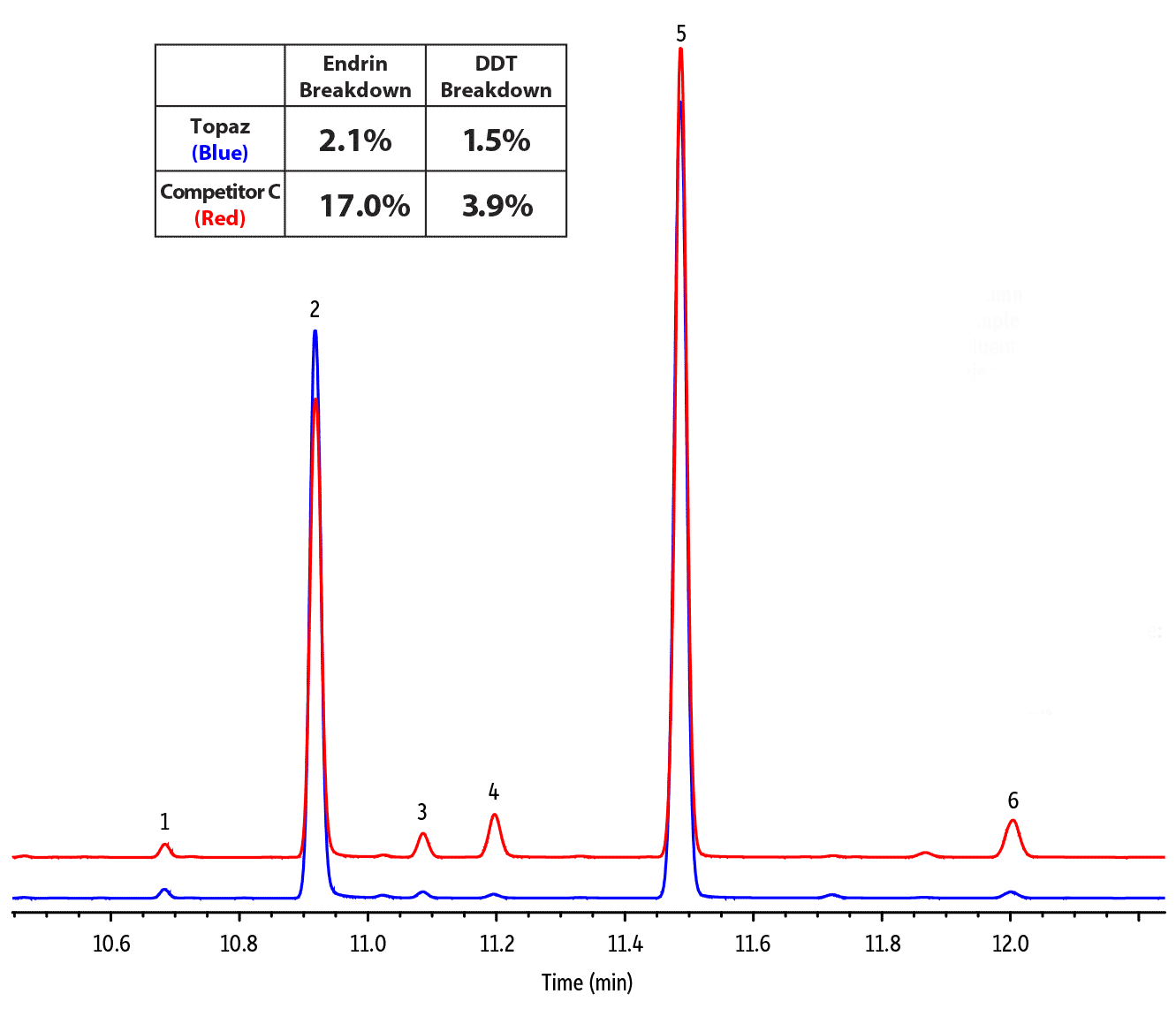

Figure 3: Government regulations can have very strict requirements for maximum analyte breakdown. For example, EPA method 8081 requires no more than 15% endrin and DDT breakdown. No problem with Topaz liners.

| Peaks | tR (min) | Conc. (ng/mL) | |

|---|---|---|---|

| 1. | 4,4'-DDE | 10.685 | * |

| 2. | Endrin | 10.920 | 50 |

| 3. | 4,4'-DDD | 11.087 | * |

| 4. | Endrin aldehyde | 11.198 | * |

| 5. | 4,4'-DDT | 11.488 | 100 |

| 6. | Endrin ketone | 12.005 | * |

| Column | Rxi-5ms, 15 m, 0.25 mm ID, 0.25 µm (cat.# 13420) |

|---|---|

| Standard/Sample | Endrin (50 ng/mL) and DDT (100 ng/mL) |

| Diluent: | n-Hexane |

| Injection | |

| Inj. Vol.: | 1 µL splitless (hold 1.2 min) |

| Liner: | Topaz 4.0 mm single taper with wool (cat.# 23303) |

| Inj. Temp.: | 250 °C |

| Purge Flow: | 20 mL/min |

| Oven | |

| Oven Temp.: | 50 °C (hold 1.2 min) to 240 °C at 20 °C/min to 265 °C at 6 °C/min |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.5 mL/min |

| Detector | ECD @ 300 °C |

|---|---|

| Make-up Gas Flow Rate: | 60 mL/min |

| Make-up Gas Type: | N2 |

| Data Rate: | 20 Hz |

| Instrument | Agilent 7890A GC |

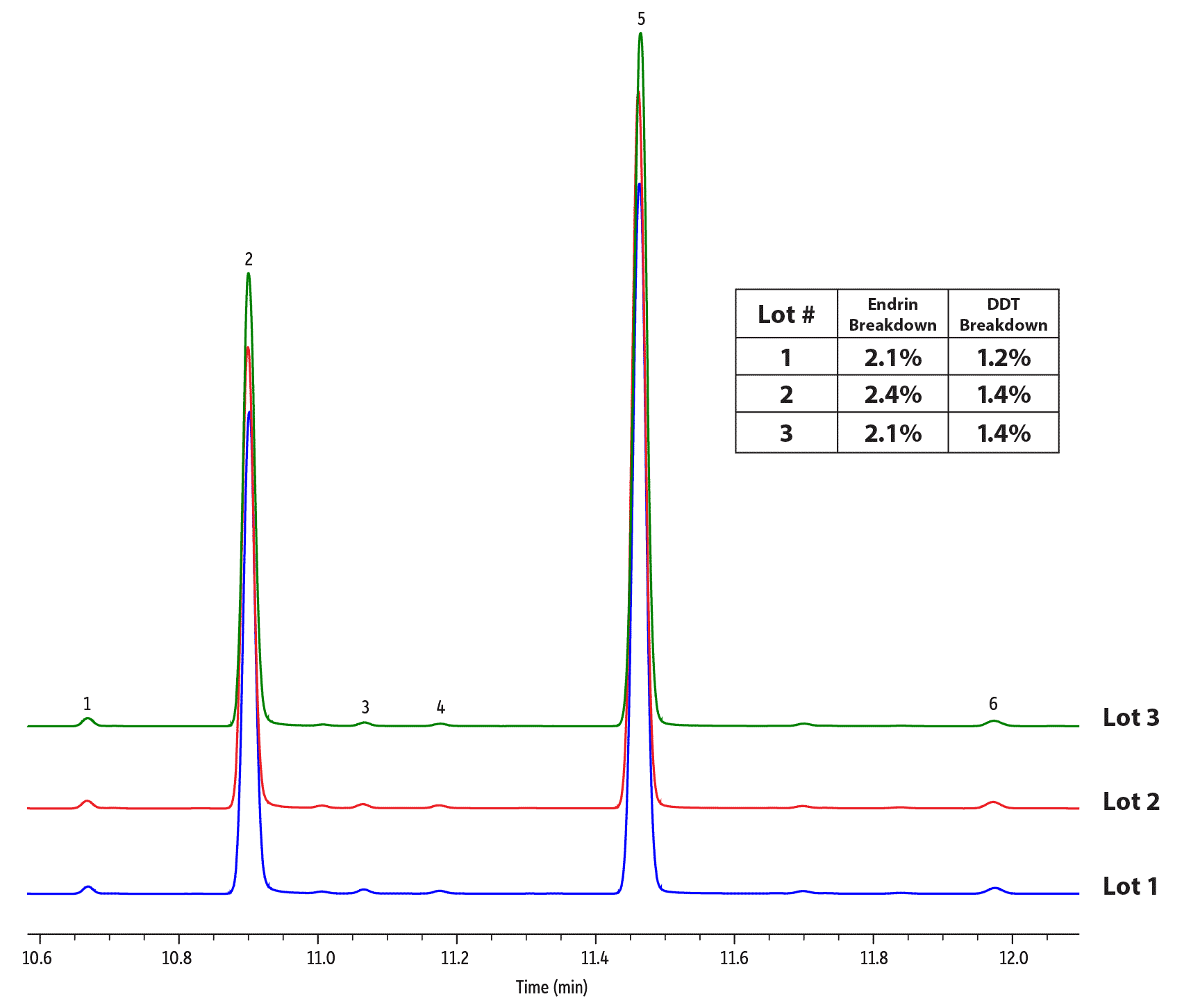

The Next Level of True Blue Reproducibility

New Topaz inlet liners are made under strict manufacturing controls, followed by a battery of industry-specific QC tests, to prove that every lot we produce maintains superior reliability and outstanding inertness across a broad range of compound classes. By ensuring the utmost reproducibility in our liners, we help eliminate frustration and uncertainty in your work.

In the end, we don’t test Topaz liners to exceed method requirements. We don’t test Topaz liners to exceed industry norms. We manufacture and QC test Topaz liners to exceed your expectations and bring you the peace of mind that you can always depend on the quality and consistency of your data. Expect more—every time—with Topaz GC inlet liners.

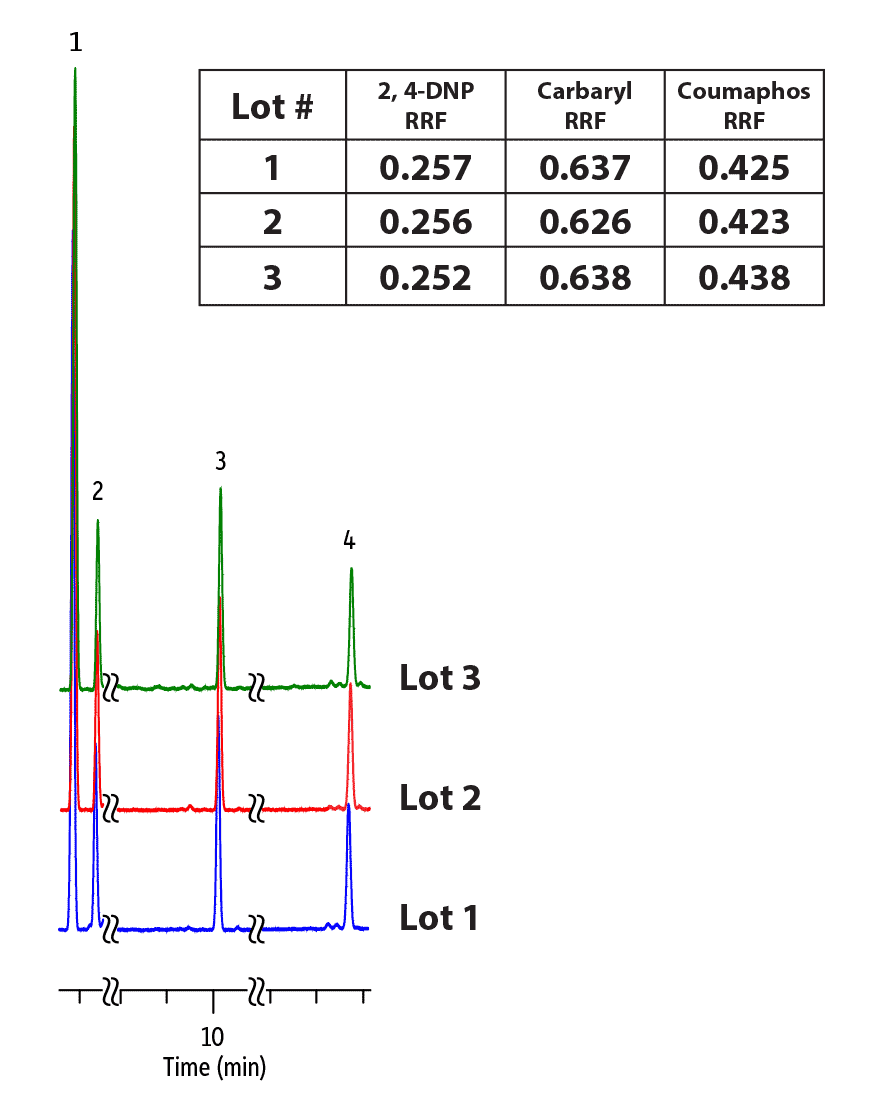

Figure 4: As shown with the low breakdown of notoriously reactive compounds like endrin and DDT—as well as high response factors for 2,4-DNP, carbaryl, and coumaphos—you can expect the same great results from one lot to the next.

| Peaks | tR (min) | Conc. (ng/mL) | |

|---|---|---|---|

| 1. | 4,4'-DDE | 10.670 | * |

| 2. | Endrin | 10.902 | 50 |

| 3. | 4,4'-DDD | 11.067 | * |

| 4. | Endrin aldehyde | 11.177 | * |

| 5. | 4,4'-DDT | 11.464 | 100 |

| 6. | Endrin ketone | 11.976 | * |

| Column | Rxi-5ms, 15 m, 0.25 mm ID, 0.25 µm (cat.# 13420) |

|---|---|

| Standard/Sample | Endrin (50 ng/mL) and DDT (100 ng/mL) |

| Diluent: | n-Hexane |

| Injection | |

| Inj. Vol.: | 1 µL splitless (hold 1.2 min) |

| Liner: | Topaz 4.0 mm single taper with wool (cat.# 23303) |

| Inj. Temp.: | 250 °C |

| Purge Flow: | 20 mL/min |

| Oven | |

| Oven Temp.: | 50 °C (hold 1.2 min) to 240 °C at 20 °C/min to 265 °C at 6 °C/min |

| Carrier Gas | He, constant flow |

| Flow Rate: | 1.5 mL/min |

| Detector | Micro-ECD @ 300 °C |

|---|---|

| Make-up Gas Flow Rate: | 60 mL/min |

| Make-up Gas Type: | N2 |

| Data Rate: | 20 Hz |

| Instrument | Agilent 7890A GC |

| Peaks | tR (min) | Conc. (µg/mL) | |

|---|---|---|---|

| 1. | Acenaphthene (IS) | 7.570 | 1.0 |

| 2. | 2,4-Dinitrophenol (DNP) | 7.668 | 1.0 |

| 3. | Carbaryl | 10.020 | 0.5 |

| 4. | Coumaphos | 13.737 | 0.5 |

| Column | Rxi-5ms, 15 m, 0.25 mm ID, 0.25 µm (cat.# 13420) |

|---|---|

| Standard/Sample | Topaz liner FID test mix |

| Diluent: | Methylene chloride |

| Injection | |

| Inj. Vol.: | 1 µL splitless (hold 1 min) |

| Liner: | Topaz 4.0 mm single taper liner with wool |

| Inj. Temp.: | 250 °C |

| Purge Flow: | 40 mL/min |

| Oven | |

| Oven Temp.: | 40 °C (hold 1 min) to 300 °C at 18.5 °C/min (hold 1 min) |

| Carrier Gas | He, constant flow |

| Flow Rate: | 2 mL/min |

| Detector | FID @ 340 °C |

|---|---|

| Make-up Gas Flow Rate: | 45 mL/min |

| Make-up Gas Type: | N2 |

| Hydrogen flow: | 40 mL/min |

| Air flow: | 400 mL/min |

| Data Rate: | 50 Hz |

| Instrument | Agilent 7890A GC |

Perfect Installation Every TimeThere is never a question about which way to install a Topaz liner—simply orient it so that the column installs towards the "R" in the Restek logo. |

|

The Next Level of True Blue Productivity

Any time spent with your instrument offline—such as when changing your GC inlet liner or conditioning it afterward—directly ties to increased cost per analysis and decreased revenue for your lab and raises the odds of yet another evening at the bench catching up on backlogged work for you. Whether you’re standing in Restek’s applications lab or at your own bench, it is imperative to keep running samples as long as possible, and when you do need to perform maintenance, to get back up and running as quickly as possible.

With the stability and inertness of a Topaz liner, you can analyze more samples before your data quality declines and you have to stop to replace your liner.

Figure 5: The stability of a Topaz liner shines compared to leading competitors. Breakdown of a reactive compound like endrin starts low and stays low, even after 40 injections.

Superior Cleanliness for Maximum UptimeTopaz liners also feature blister packaging developed for superior cleanliness. The cleaner the liner, the less time you spend conditioning after changing your liner. Greater instrument uptime translates into more samples run and more profit for your lab. Get it with the unparalleled stability and cleanliness of Topaz inlet liners. |

|

What Will You Lose When You Switch to Topaz Liners?

Revolutionary Topaz deactivation results in unbelievably low breakdown and higher responses for active compounds—with each and every liner you order. These liners will help you generate more accurate and more precise low-level GC analyses and help prevent common data issues.

What Will You Gain? Productivity.

Extend your uptime and generate more revenue with Topaz liners.

Turn to the Ultimate in Deactivation, Reproducibility, and Productivity

Give yourself, your lab, and your customers the confidence you need in the data you generate—and the ability to keep your instruments running longer. Order your Topaz GC inlet liners today.

Quantity discounts available for orders of five or more 5-packs!